Stricter environmental regulations coupled with an increasing focus on sustainability in the Metalworking Industry, has led to the replacement of straight oil formulations by emulsifiable, semi-synthetic and synthetic formulations.

Synative AC LF 420 is a GHS Label free, non-ionic emulsifier based on vegetable raw materials that offers salient advantages to fluid manufacturers sensitive to environmental health & safety (EHS) concerns when compared to other Fatty Alcohol Ethoxylates.

GHS Label Comparison

Emulsifier for Metalworking Fluids

Labeling of Alcohol Ethoxylates

- Alchohol ethoxylates exhibit aqua toxicity labeling depending on the degree of ethoxylation (according to CESIO CLP classification)

- Synative AC LF 420 has been developed as a low-foaming label free emulsifier without aqua toxicity

| C18 Alcohol, ethoxylated | Hazard Statement | CLP Pictogram |

|---|---|---|

| ≤ 5 mol EO | H 411 (toxic to aquatic life with long lasting effects) | |

| > 5 mol EO ≤ 7 mol EO | H 400 (very toxic to aquatic life) H412 (harmful to aquatic life with long lasting effects) |

|

| > 7 mol EO ≤ 10 mol EO | H 400 (very toxic to aquatic life) | |

| > 10 mol EO | None | None |

Synative AC LF 420

Ecotoxicological Data

|

Fatty Alcohol Ethoxylate |

Synative AC LF 420 (Fatty Alcohol Alkoxylate) |

|

|---|---|---|

| Product | ||

| Hazard Statement | H 315 (causes skin irritation) H 411 (toxic to aquatic life with long lasting effects) |

None |

| CLP Pictogram | None | |

| Formulation (<25% Emulsifier) | ||

| Hazard Statement | H 412 (harmful to aquatic life with long lasting effects) | None |

| CLP Pictogram | None |

Synative AC LF 420 is not just an improvement in sustainability, it is versatile and has enhanced functional qualities.

Solubility

Synative AC LF 420

Solubility in Base Oils

Solubility in different base oils (5% emulsifier, room temperature)

Synative AC LF 420 is highly soluble in a wide range of base oils; solutions are clear at room temperature

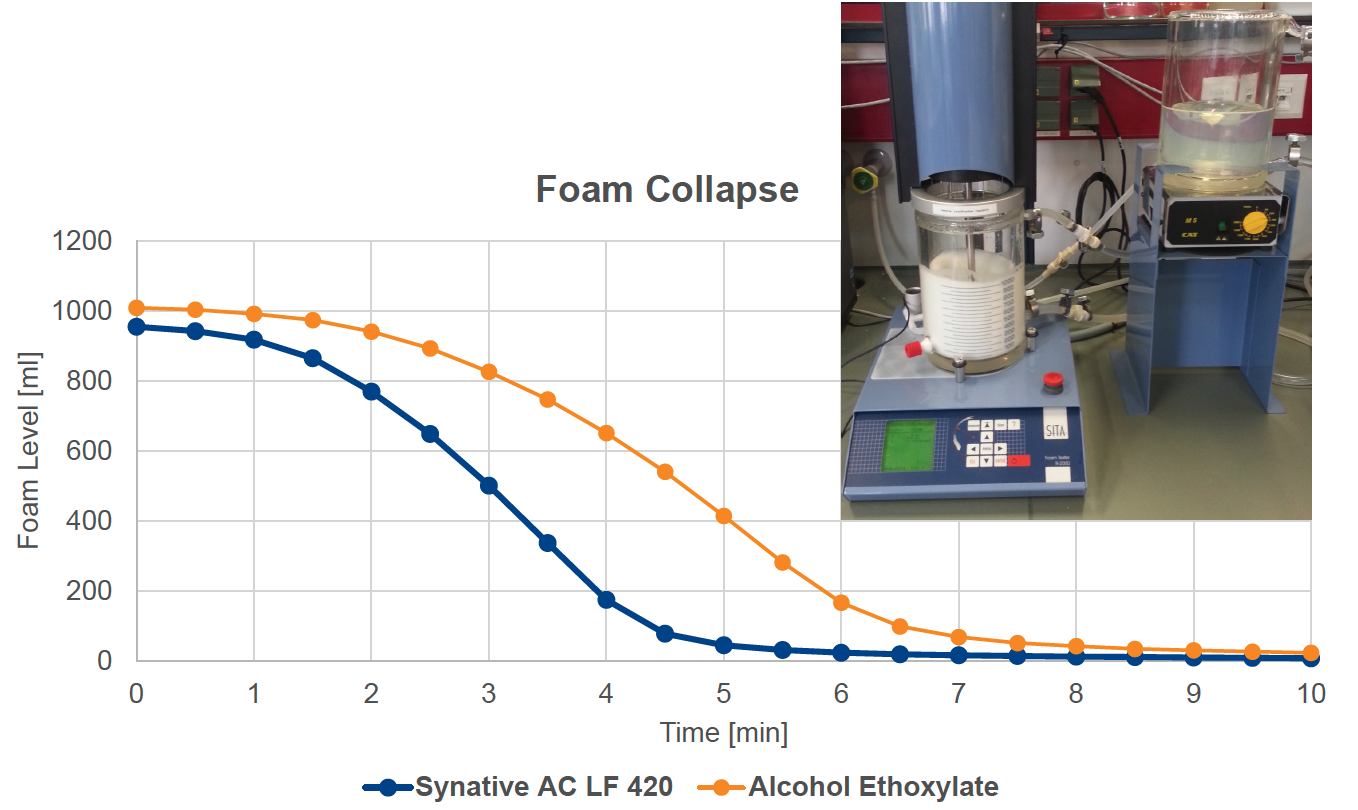

Foaming

Synative AC LF 420

Foam Behavior

Synative AC LF 420 shows superior low foaming properties compared to typical alcohol ethoxylates

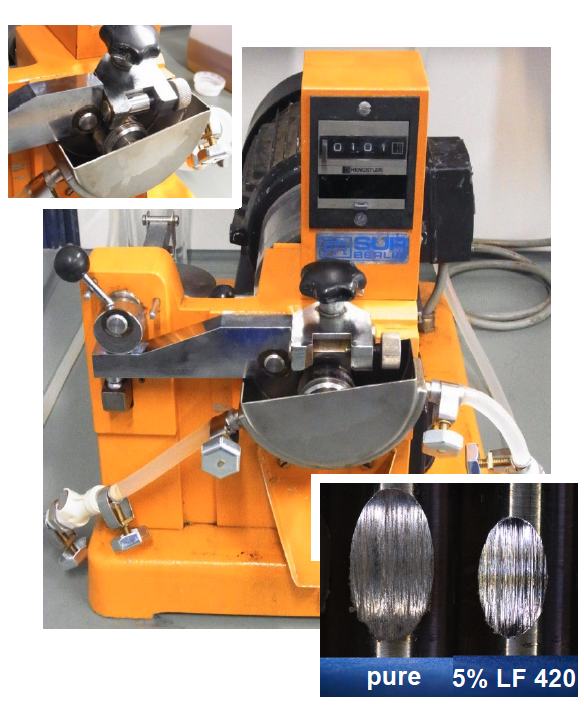

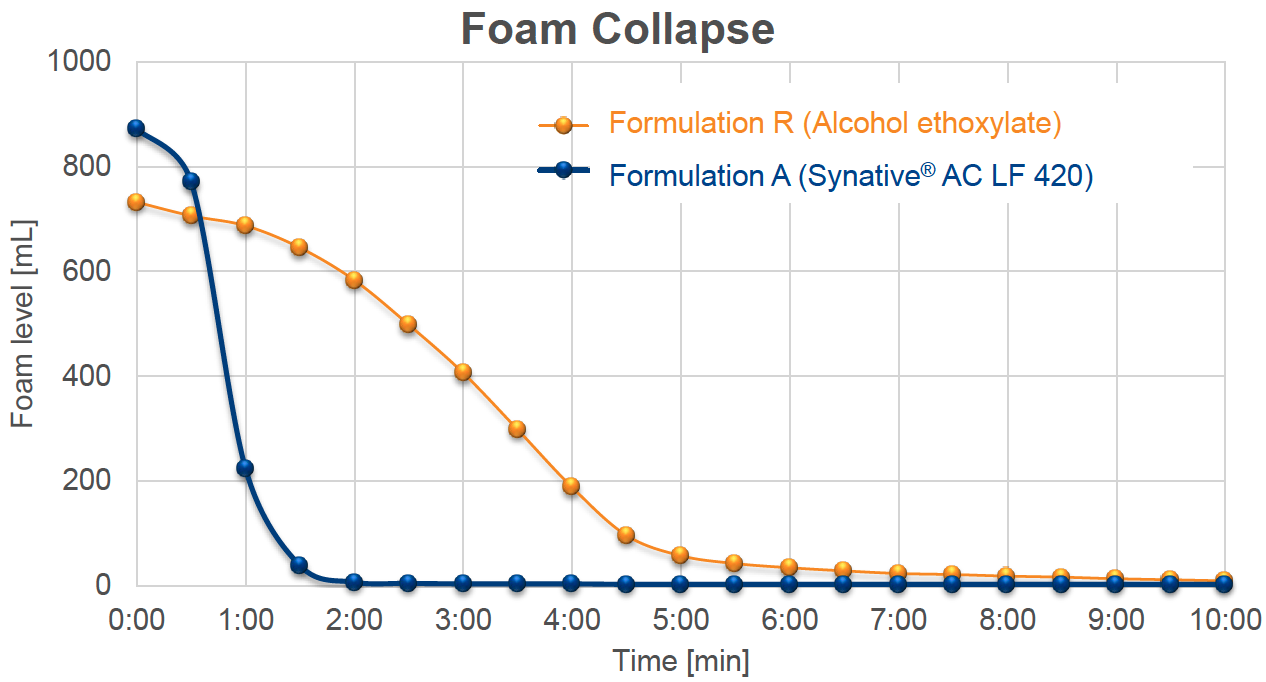

Lubricity

Synative AC LF 420

Lubricity – Reichert Wear Scar

Test Conditions

- Room temperature, sliding speed 1.7 m/s, 1.5 kg load, 100 m travel path

- Formulation with naphthenic base oil (Nynas T 22, Reichert wear scar: 40 mm²)

- Comparison to alcohol ethoxylate emulsifier and TMP oleate (KV40 = 46 mm²/s)

Synative AC LF 420 shows excellent lubricity, superior to TMP oleate and comparable to ethoxylates

Where Synative AC LF 420 demonstrates its utility is in formulation, employed as an emulsifier in a generic semi-synthetic metalworking fluid, a clear and stable emulsion is obtained.

Semi-Synthetic Formulation

Synative AC LF 420

Application in Semi-Synthetic Formulation – Composition

Formulation

| Concentrate formulation (%) | Concentrate R | Concentrate A |

|---|---|---|

| Amines + boric acid | 13.8 | 13.8 |

| Distilled water | 3.9 | 3.9 |

| Tall oil fatty acid (TOFA) | 14.3 | 14.3 |

| Coupling agent | 3.6 | 3.6 |

| Synative AC 3499 | 3.6 | 3.6 |

| Synative AC 3370 V | 3.6 | 3.6 |

| Alcohol ethoxylate | 7.2 | – |

| Synative AC LF 420 | – | 7.2 |

| Naphtenic mineral oil | 50.0 | 50.0 |

- Stability of concentrates: 0°C, 50°C, room temperature (> 7 days)

- Concentrates mixed with water (20°dH / ca. 360 ppm CaCO3) result in transparent micro emulsion

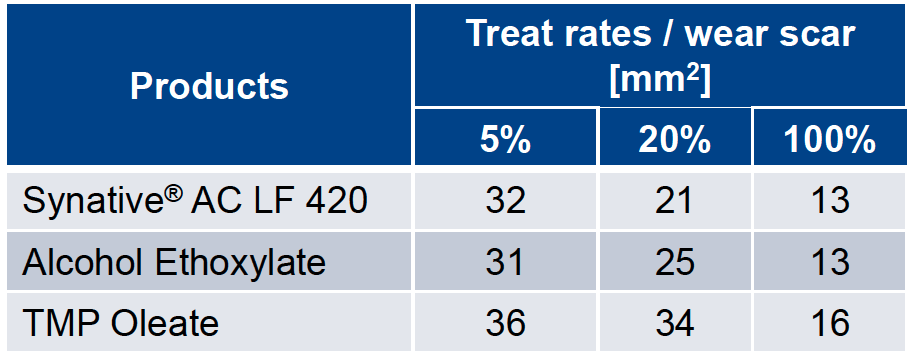

In the same formulation the variable utilizing Synative AC LF 420 shows a significant decrease in the foam collapse time compared to the conventional alcohol ethoxylate variable.

Foaming Comparison

Synative AC LF 420

Application in Semi-Synthetic Formulation – Foaming Behavior

Semi-synthetic formulations based on Synative AC LF 420 exhibit superior low foaming behavior

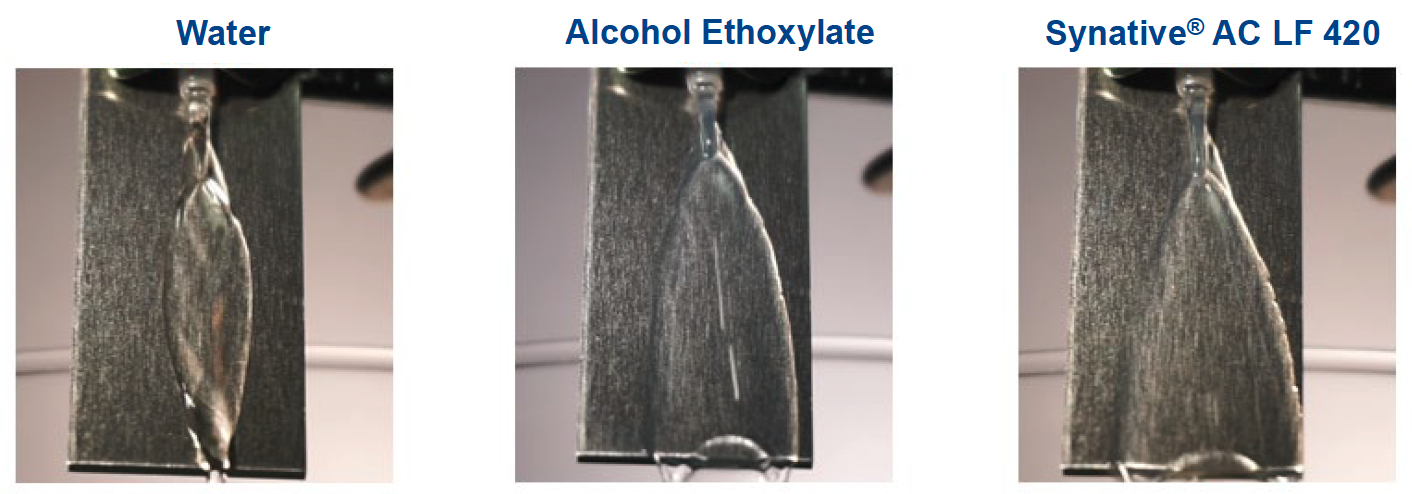

The Synative AC LF 420 variable also demonstrates superior wetting functionality.

Wetting Properties Comparison

Synative AC LF 420

Application in Semi-Synthetic Formulation – Wetting Behavior

AI alloy (6061 T6), position: 45° angle

Synative AC LF 420 shows excellent wetting properties in semi-synthetic formulations

Formulations using Synative AC LF 420 also exhibit a capacity to withstand hard water, maintaining a stable and clear emulsion.

Hard Water Stability

Synative AC LF 420

Application in Semi-Synthetic Formulation – Stability

Formulations tolerate hard water conditions

- 20°dH (≈ 400 ppm CaCO3): Stability > 7 days transparent micro emulsion

- 40°dH (≈ 700 ppm CaCO3): Stability > 7 days transparent micro emulsion

- 60°dH (≈ 1100 ppm CaCO3): Stability > 7 days slightly milky

- 80°dH (≈ 1400 ppm CaCO3): Stability > 6 days milky

Formulations based on Synative AC LF 420 are stable under hard water conditions

In Summary

In a competitive marketplace where manufacturers/formulators of metalworking fluids need components that are sustainable in respect to both the environment and the workplace, BASF’s Synative AC LF 420 is a hydrophilic emulsifier that contributes the following EHS and performance characteristics:

- GHS Label free component (no aqua toxicity or human hazard)

- Based of vegetable raw materials

- Optimized waste management

- Clear and stable emulsions

- Solubility in a wide range of base oils

- HLB ≈ 10

- Excellent lubricity

- Superior wetting

- Hard water tolerance

- Globally registration

Chris Sementa, Technical Director – Monson