Current metalworking industry trends towards smaller machine sumps and higher speed, higher pressure machining continue to increase the demand for very low foaming lubricity additives. Modern metals and tooling require new metalworking fluid solutions that offer a step up in lubricity versus conventional systems.

Our Solution

Synative LE 6000 from BASF is a novel lubricity enhancer with superior performance and efficiency. It complements current conventional block co-polymer chemistries for use in fully and semi-synthetic MWF formulations. It offers formulators significant performance advantages over existing lubricant additives (see Key Features and Benefits) as well as cost savings with achieving benefits at lower treat rates.

Solubility and cloud points vs. conventional block co-polymers

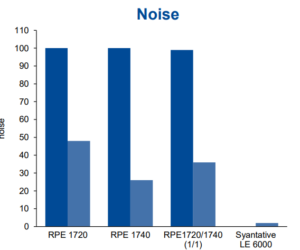

Lower wear scar and noise vs. conventional block co-polymers (Reichert test)

Test condition: components tested; Steel100Cr6, 1.70 m/sec; 294 N

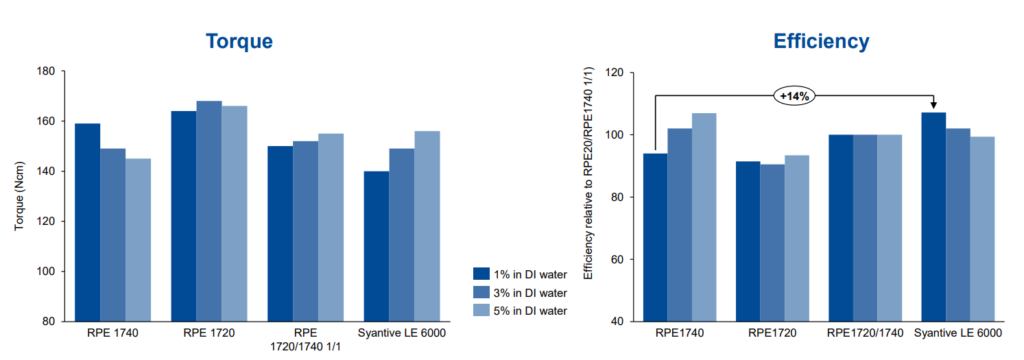

Efficient reduction of torque at low treat rate

Test condition: Steel 1.173, 600 rpm, 10mm, M4F-TINT 3.641mm; 1%, 3%, 5% in DI water, Synative LE 6000 may not be fully soluble in water.

Very low foaming performance – Circulation foaming (CNOMO)

Test conditions

- 0.1% in distilled water/BDG (85/15)

- Results after 10 min foam generation

- 192 l/h flow rate

Results

- Source of foam is BDG in water

- Most additives do not significantly add to the foaming behavior

- No foam after 30 sec

Test condition: SITA, 1500 rpm, 1% in distilled water/BDG (8/2)

The Ideal Addition

SYNATIVE LE 6000’s unique key features and benefits make it an ideal addition to the formulator’s toolbox:

- Superior performance compared to block co-polymers

- High efficiency at low treat rate

- Efficient reduction of torque

- Low wear scar and noise

- Very low foaming

- Excellent wetting due to low surface tension

- High separation power for improved cleanliness

- Broad registration

- No labeling

BASF’s new high performance lubricity additive Synative LE 6000 is here to meet your future formulation requirements. Contact us for more information and to request a sample.